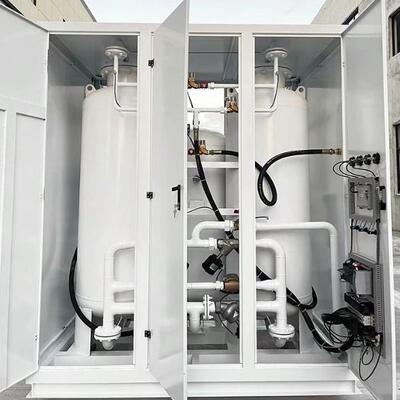

Gas Nitrogen Generator PSA Pressure Swing Adsorption High Flow High Purity Nitrogen Generator

A PSA nitrogen generator (Pressure Swing Adsorption nitrogen generator) is an advanced industrial gas separation device designed to deliver high-flow, high-purity nitrogen via the Pressure Swing Adsorption (PSA) principle. By leveraging the selective adsorption properties of carbon molecular sieve (CMS) for oxygen and nitrogen, it efficiently extracts nitrogen from ambient air, achieving purity levels up to 99.999% while maintaining large-scale gas output. Its defining advantage of onsite nitrogen generation eliminates the logistical constraints of cylinder or liquid nitrogen supply, ensuring continuous, on-demand nitrogen for high-volume industrial processes. As a dual-performance high-purity nitrogen generator and high-flow solution, it combines energy efficiency, automated operation, and robust design—making it a cornerstone for industries requiring both large gas volumes and uncompromised purity. With scalable configurations, it adapts to diverse industrial needs, from heavy manufacturing to precision engineering.

Core Technical Parameters

| Nitrogen Production (Nm³/h) |

Effective Air Consumption (Nm³/min) |

Inlet Pipe Size (DNmm) |

Outlet Pipe Diameter (DNmm) |

Host L × W (mm) |

| 5 |

0.7 |

25 |

15 |

1150×600 |

| 10 |

1.4 |

25 |

15 |

1250×880 |

| 20 |

2.8 |

40 |

15 |

1750×1000 |

| 30 |

4.2 |

40 |

25 |

2150×1100 |

| 40 |

5.6 |

50 |

25 |

2250×1140 |

| 50 |

7.0 |

50 |

25 |

2500×1150 |

| 60 |

8.4 |

50 |

25 |

2750×1450 |

| 80 |

11.2 |

65 |

32 |

2750×1450 |

| 100 |

14.0 |

65 |

32 |

2850×1550 |

| 200 |

28.0 |

65 |

32 |

3250×1820 |

| 300 |

42.0 |

80 |

40 |

3500×2150 |

Working Principle

The PSA nitrogen generation system operates through a cyclic adsorption-desorption process optimized for high-flow, high-purity output. Compressed air first undergoes multi-stage filtration (oil, water, dust, and hydrocarbon removal) to ensure clean air enters the adsorption towers—critical for protecting the CMS and maintaining purity. The purified air is then directed into parallel adsorption towers filled with CMS: under specific pressure, oxygen molecules are rapidly adsorbed by the sieve, while nitrogen molecules (with weak adsorption affinity) pass through to form high-purity product gas. As one tower approaches saturation, the system automatically switches to alternate towers for uninterrupted flow, while the saturated tower undergoes depressurization and purge regeneration to release adsorbed oxygen. This advanced cyclic design—enhanced for high-flow scenarios—ensures the PSA nitrogen plant working efficiency remains above 96% even at maximum flow rates, delivering consistent purity and volume for industrial-scale operations.

Key Industrial Applications

- Petrochemical & Refining: Used for inert gas blanketing, pipeline purging, and catalyst protection in oil refineries and chemical plants. High-flow nitrogen displaces oxygen to prevent explosions and oxidation, while 99.999% purity avoids contaminating sensitive chemical processes. Optional explosion-proof nitrogen generator configurations ensure safety in hazardous environments.

- Metallurgy & Heat Treatment: Provides large-volume protective gas for steelmaking, aluminum processing, and metal heat treatment. Nitrogen prevents oxidation and decarburization of metals during high-temperature processes, improving product quality and yield. The high-flow design matches the throughput of continuous casting and forging lines.

- Electronics & Semiconductor Manufacturing: Critical for wafer fabrication, chip packaging, and semiconductor assembly. High-purity nitrogen (99.999%+) eliminates moisture and oxygen, preventing defects in sensitive electronic components. The high-flow capability supports mass production lines in electronics factories.

- Food & Beverage Processing: Used for large-scale modified atmosphere packaging (MAP) of bottled drinks, canned foods, and frozen products. High-flow nitrogen flushes packaging quickly and efficiently, extending shelf life by displacing oxygen. It meets FDA and ISO 22000 standards for food contact safety.

- Pharmaceutical Production: As a pharmaceutical grade PSA nitrogen generator, it delivers high-purity, oil-free nitrogen for drug manufacturing, sterile packaging, and API (Active Pharmaceutical Ingredient) processing. The high-flow design supports bulk production while complying with GMP standards.

Core Advantages

- Dual Performance Excellence: Balances high flow rates (up to 5000 Nm³/h) with ultra-high purity (up to 99.999%), meeting the needs of both large-scale and precision processes.

- Energy Efficiency: As a high-efficiency PSA nitrogen generator, it optimizes adsorption cycles, reduces pressure loss, and minimizes power consumption—lowering operational costs by 25-30% compared to conventional high-flow nitrogen systems.

- Scalable Modular Design: Available as a modular nitrogen generator, it allows capacity expansion by adding independent modules, adapting to growing production demands without replacing the entire system.

- 24/7 Continuous Operation: Multi-tower parallel configuration ensures uninterrupted nitrogen supply, even during tower regeneration or maintenance—critical for non-stop industrial processes.

- Advanced Automation: PLC control system with real-time monitoring and remote operation capabilities reduces manual intervention, improves process stability, and enables predictive maintenance.

- Cost Savings: Onsite nitrogen gas generation eliminates costs associated with nitrogen cylinder/liquid nitrogen transportation, storage, and rental—delivering long-term ROI for high-volume users.

Selection Considerations

- Flow & Purity Matching: Ensure the generator's flow rate aligns with your peak production demand and purity meets industry-specific standards.

- Energy Efficiency: Prioritize energy-saving nitrogen generator models with optimized CMS and adsorption cycles to reduce long-term operational costs.

- Structural Reliability: Select a robust design with corrosion-resistant materials and multi-tower configuration to withstand heavy industrial environments.

- Customization Capabilities: Partner with a PSA nitrogen plant manufacturer offering modular expansion, pressure upgrades, or explosion-proof configurations.

- Purity Monitoring & Control: Opt for systems with online purity analyzers and automatic adjustment features to maintain consistent purity.

- After-Sales Support: Choose a reputable PSA nitrogen generator manufacturer with global service networks and professional installation/training services.

Maintenance & Care

- Filter Maintenance: Replace pre-filter elements every 2-4 months (more frequently for dusty environments) to prevent contamination of the CMS.

- CMS Replacement: The high-capacity CMS has a service life of 4-6 years; monitor adsorption efficiency and replace when purity drops below threshold.

- Tower & Pipeline Inspection: Check adsorption towers and pipelines for leaks quarterly to maintain operating pressure stability.

- Control System Calibration: Calibrate pressure sensors, flow meters, and purity analyzers annually to ensure accurate monitoring.

- Environment Management: Install the generator in a well-ventilated, dry area with temperature control (5-45℃) to prevent component damage.

Conclusion

The Gas Nitrogen Generator PSA Pressure Swing Adsorption High Flow High Purity Nitrogen Generator represents the pinnacle of industrial nitrogen production, combining high-volume output with ultra-pure performance to meet the most demanding industrial needs. As a core PSA nitrogen generator variant, it delivers onsite nitrogen generation efficiency, energy savings, and scalability—making it indispensable for petrochemical, metallurgy, electronics, pharmaceutical, and food processing industries. Whether you require a modular nitrogen generator for flexible expansion, a high purity 99.999% N2 generator for precision applications, or an explosion-proof nitrogen generator for hazardous environments, our customizable solutions are engineered to exceed expectations. As a trusted PSA nitrogen generator manufacturer, we prioritize quality, reliability, and customer-centricity—backing our products with comprehensive warranties and global after-sales support.

In addition to PSA Nitrogen Generator, we also produce VPSA Oxygen Generators, PSA Oxygen Generators, storage tanks, heat exchangers and other products. If you are interested in PSA nitrogen systems or other products, please contact us at info@gneeheatex.com. We will be very happy to serve you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!